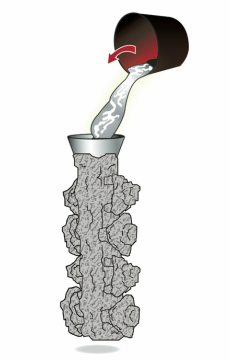

Step 5: Metal Pouring

Before the metal is poured into the ceramic mold or “shell”, the mold is preheated to a specific temperature to prevent the molten alloy from solidifying or “freezing off” before the entire mold is filled.

Alloy is melted in a ceramic cup (called a crucible) using a process known as induction melting. A high frequency electric current creates a magnetic field around the alloy, generating electric fields inside the metal (eddy currents). The eddy currents heat the alloy due to the material’s electrical resistance. When the alloy reaches its specified temperature, it is poured into the mold, and the mold is allowed to cool. Next... Step 6: Shell Knock Off Back... What Is Investment Casting |

Quick Links

|